Water and Wastewater Treatment

Reservoirs And Pump Stations

TJCAA provided analyses, recommendations, and construction cost-benefit analysis for replacing the roof of the Gauntlett and Iversen Reservoirs, two lined, earthen reservoirs. As part of this project, TJCAA inspected the reservoirs, assessed condition, and performed preliminary structural analysis. TJCAA identified replacement roof system options for the Gauntlett Reservoir with consideration given to three scenarios including the potential for installation of rooftop solar arrays.

TJCAA provided analyses, recommendations, and construction cost-benefit analysis for replacing the roof of the Gauntlett and Iversen Reservoirs, two lined, earthen reservoirs. As part of this project, TJCAA inspected the reservoirs, assessed condition, and performed preliminary structural analysis. TJCAA identified replacement roof system options for the Gauntlett Reservoir with consideration given to three scenarios including the potential for installation of rooftop solar arrays.

The project addressed operational issues at a lift station including design improvements for motors and drives, updating control systems, and electrical servicing. TJCAA’s design team developed sequence of construction, phased service replacement, drive replacement, and infrastructure improvements to ensure continuous pump availability during construction. Additionally, the project included upgrades to the facility’s SCADA system RTU controls, including new hot standby redundant PLCs and backup PLC controls to eliminate pump station vulnerability to single points of failure.

The project addressed operational issues at a lift station including design improvements for motors and drives, updating control systems, and electrical servicing. TJCAA’s design team developed sequence of construction, phased service replacement, drive replacement, and infrastructure improvements to ensure continuous pump availability during construction. Additionally, the project included upgrades to the facility’s SCADA system RTU controls, including new hot standby redundant PLCs and backup PLC controls to eliminate pump station vulnerability to single points of failure.

TJCAA provided structural design and construction services for the 1-MG, welded steel recycled water tank and supporting pump stations. This project, which provided service for a golf course recycled water system, required coordination with two agencies: those of both the water purveyor (Delta Diablo Sanitation District) and the end user. To meet cost objectives, TJCAA’s clients elected to use pre-cast units for all of the support structures, vaults, and manholes. TJCAA provided a low-profile tank design that accommodated the needs of the constrained site, which was within the City of Pittsburg’s Delta View Golf Course. The main pump station building was a prefabricated masonry unit, and the building for the booster pump station was of prefabricated, fiber-reinforced plastic.

TJCAA provided structural design and construction services for the 1-MG, welded steel recycled water tank and supporting pump stations. This project, which provided service for a golf course recycled water system, required coordination with two agencies: those of both the water purveyor (Delta Diablo Sanitation District) and the end user. To meet cost objectives, TJCAA’s clients elected to use pre-cast units for all of the support structures, vaults, and manholes. TJCAA provided a low-profile tank design that accommodated the needs of the constrained site, which was within the City of Pittsburg’s Delta View Golf Course. The main pump station building was a prefabricated masonry unit, and the building for the booster pump station was of prefabricated, fiber-reinforced plastic.

Key Features:

- Low-Profile Tank Design

- Pump Stations

- Highly Constrained

This project included structural design and construction management services for a 2,176-square-foot wastewater pump station/electrical building. The design for this large concrete masonry unit used a double hip roof and other architectural features that allowed the structure to blend with its setting in the Ruby Hill area of Pleasanton, California. The design for this pump station was further constrained by the need to maintain clearances on the site, which was next to a fire station. This project required coordination with multiple entities, including the lead firm Garber Engineering and the City of Pleasanton. TJCAA also provided services during construction.

This project included structural design and construction management services for a 2,176-square-foot wastewater pump station/electrical building. The design for this large concrete masonry unit used a double hip roof and other architectural features that allowed the structure to blend with its setting in the Ruby Hill area of Pleasanton, California. The design for this pump station was further constrained by the need to maintain clearances on the site, which was next to a fire station. This project required coordination with multiple entities, including the lead firm Garber Engineering and the City of Pleasanton. TJCAA also provided services during construction.

Key Features:

- Constrained Site

- Architectural/Aesthetic Requirements

- Coordination with Multiple Entities

Buildings and Structures

Novato Sanitary District, Seismic Evaluations

TJCAA performed structural evaluations of digesters (concrete structures) at the District’s WWTP and deep bed filters and secondary clarifiers for the District’s tertiary treatment facility. TJCAA’s evaluations identified seismic vulnerability, verified code compliance, and determined locations for new equipment in existing structures. TJCAA evaluated options for placement of filtration, disinfection with UV or chlorine, and residual disinfection systems at the recycled water facility. Emphasis was put on finding options for reuse of existing structures.

Brentwood, WWTP Expansion Project

The Brentwood WWTP Expansion Project, with a construction value of over $48 million, included replacement of an existing plant while the existing plant remained operational until completion of the new facilities. TJCAA provided structural design, predesign, design, and construction services for the entire upgrade facility as part of the G.S. Dodson & Associates, Inc. team.

City of Belmont-Recreation Facility

Structural design of a two story concrete block recreation facility and two concession/restroom buildings for new softball fields.

City of Glendale- Groundwater Remediation Project

Structural design of facilities associated with this ground water remediation project. Elements included seismic anchorage, operations facilities, chemical storage, groundwater well vaults and a 240 foot clear span pipe crossing over an existing water channel in Glendale, CA. The project required mat foundations to accommodate potential settlement from the existing unconsolidated soils.

Electrical

Instrumentation and Control

The PLC upgrade project for a 21-mgd water treatment plant modernized an obsolete PLC system. TJCAA performed field investigations to update the as-built wiring diagrams, system design narratives, and coordination spreadsheet and programmed the new system to use the client’s existing control logic. In coordination with ACWD staff, TJCAA performed I/O testing, SCADA testing, and functional testing that simulated process inputs before the equipment was installed. TJCAA’s work on this project also included equipment commissioning, including operational readiness testing and functional acceptance testing.

The PLC upgrade project for a 21-mgd water treatment plant modernized an obsolete PLC system. TJCAA performed field investigations to update the as-built wiring diagrams, system design narratives, and coordination spreadsheet and programmed the new system to use the client’s existing control logic. In coordination with ACWD staff, TJCAA performed I/O testing, SCADA testing, and functional testing that simulated process inputs before the equipment was installed. TJCAA’s work on this project also included equipment commissioning, including operational readiness testing and functional acceptance testing.

The project addressed operational issues at a lift station including design improvements for motors and drives, updating control systems, and electrical servicing. TJCAA’s design team developed sequence of construction, phased service replacement, drive replacement, and infrastructure improvements to ensure continuous pump availability during construction. Additionally, the project included upgrades to the facility’s SCADA system RTU controls, including new hot standby redundant PLCs and backup PLC controls to eliminate pump station vulnerability to single points of failure.

The project addressed operational issues at a lift station including design improvements for motors and drives, updating control systems, and electrical servicing. TJCAA’s design team developed sequence of construction, phased service replacement, drive replacement, and infrastructure improvements to ensure continuous pump availability during construction. Additionally, the project included upgrades to the facility’s SCADA system RTU controls, including new hot standby redundant PLCs and backup PLC controls to eliminate pump station vulnerability to single points of failure.

United Water of Idaho, Columbia Water Treatment Plant: Design/Build of ultra-filtration membrane treatment process. Project required development of electrical and I&C documents at a level sufficient for construction permitting and to develop a guaranteed maximum price (Design/CM at Risk).

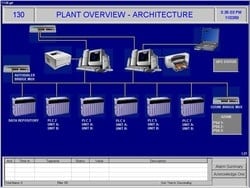

City of Santa Cruz, Graham Hill Water Treatment Plant Control System Upgrade: System upgrade project including vendor selection, system design, panel fabrication, coordination of subcontractors, installation, startup, testing, training, and follow-up/warranty tasks. The resulting SCADA system includes hot standby, redundant PLCs, updated plant control strategies, human/ machine interface software, RAID Category central workstations, and 30 remote radio telemetry units.

City of Folsom, Water Treatment Plant Control System Upgrade Design/Build: The control system architecture was designed to accommodate a doubling of plant capacity without modifications to the control system approach. The suitability of the approach was confirmed during subsequent plant expansion. Design/build approach included design of control system architecture and interface to remote telemetry, fabrication/installation of PLC back panels, testing and startup.

Seattle Public Utilities, Tolt Water Treatment Plant: Design/build grassroots 120 MGD treatment plant that included ozonation, flocculation, filtration, chemical feed, solids handling, and on site clear well storage. For the instrumentation and control system, a distributed control approach was used